Supporting Innovation and Productivity in Manufacturing

Vietnam’s manufacturing sector continues to expand rapidly, with increasing demand for higher product quality, faster development cycles, and greater efficiency in production processes. To stay competitive, engineering teams need design and simulation tools that are powerful, reliable, and easy to integrate into existing workflows. SOLIDWORKS, provided and supported by SEACAD Technologies, has become a preferred solution for manufacturers seeking to elevate product development and streamline operations.

A Complete Platform from Design to Production

SOLIDWORKS is known for its intuitive 3D modeling environment, comprehensive simulation capabilities, and strong support for manufacturing preparation. It enables engineers to create detailed designs, evaluate performance early, and generate accurate documentation that keeps all departments aligned. This unified workflow reduces time spent on manual revisions and accelerates the journey from concept to finished product.

Key Advantages for Manufacturing Teams

- Clear design intent and revision control

- Efficient handling of complex assemblies

- Built-in tools for sheet metal, machining, and fabrication

- Simulation that validates structural and thermal performance

- Smooth collaboration across engineering and production teams

With these capabilities working together, manufacturers are able to respond quickly to changing requirements and deliver products that meet both performance and cost expectations.

Local Support Makes the Difference

While software functionality is important, ongoing support and guidance are equally essential. SEACAD Technologies provides structured onboarding, certified training programs, and responsive technical assistance to ensure teams not only use the software but use it effectively. This hands-on support helps organizations adopt best practices, maintain consistent output, and confidently scale their engineering operations over time.

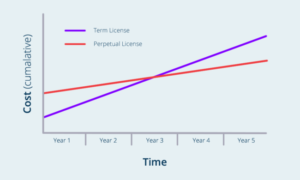

SolidWorks price

Understanding the cost of implementation is an important part of planning. SEACAD provides transparent pricing guidance and helps organizations choose the right license type based on team size, workflow requirements, and long-term objectives. This ensures companies invest in a configuration that matches their capabilities and growth plans, without unnecessary expense.

PLM software

For manufacturers seeking stronger control over product data and lifecycle workflows, product lifecycle management solutions help manage revisions, document releases, and multi-team collaboration. These tools support clarity, consistency, and accountability, especially when projects involve large assemblies or multiple stakeholders across departments or facilities.

Partnering for Long-Term Success

Beyond software delivery, SEACAD offers continuous improvement support—helping teams refine processes, adopt new features, and expand capabilities as business requirements evolve. This partnership-driven approach is what makes SEACAD a trusted choice for Vietnam’s growing industrial sector.

Empowering the Future of Manufacturing in Vietnam

Manufacturers choose SOLIDWORKS through SEACAD Technologies because the combination of powerful tools and local expertise enables efficient, accurate, and scalable engineering workflows. Together, they provide the foundation for innovation, quality, and sustainable competitiveness.