Labelling plays a crucial role in product packaging, affecting everything from brand recognition to regulatory compliance. An automatic label applicator has emerged as a transformative tool in the labelling process, offering significant advancements over traditional manual methods. This article explores the capabilities, benefits, and future of automatic label applicators, highlighting why they are indispensable in modern packaging.

What Is an Automatic Label Applicator?

An automatic label applicator is a sophisticated piece of machinery designed to apply labels to products and packaging with precision and speed. Unlike manual labelling, which can be time-consuming and prone to errors, automatic label applicators streamline the process. These machines are capable of handling various types of labels and packaging formats, including wrap-around, top and bottom, and side labelling.

The core components of an automatic label applicator include a label dispenser, a sensor system, and a label application mechanism. The dispenser feeds labels from a roll or printer, while sensors detect the product’s position, ensuring accurate placement. The application mechanism then affixes the label to the product, maintaining high standards of consistency and efficiency.

How Automatic Label Applicators Improve Efficiency

Automatic label applicators offer substantial improvements over manual labelling processes. One of the primary advantages is their ability to significantly increase production speed. These machines can handle large volumes of products swiftly, reducing bottlenecks in the production line. This speed translates to higher throughput and the capacity to meet large-scale demands.

Accuracy is another critical benefit. Automatic label applicators are designed to apply labels with a high degree of precision, minimising errors and ensuring that each product is labelled correctly. This not only enhances the overall quality of the product but also helps in maintaining compliance with industry standards.

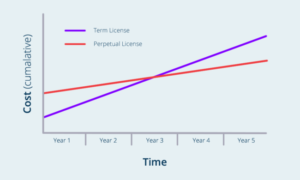

Cost-effectiveness is a long-term benefit of adopting automatic label applicators. While the initial investment might be substantial, the reduction in labour costs and the increase in productivity lead to a favourable return on investment. Over time, the savings on labour and the efficiency gains contribute to overall cost reductions.

Key Features to Consider When Choosing an Automatic Label Applicator

When selecting an automatic label applicator, several key features should be considered to ensure it meets your specific needs.

- Speed and Capacity: The machine’s speed should match the production requirements. Higher speeds are essential for high-volume production lines.

- Compatibility: Ensure that the applicator can handle the types of labels and packaging you use. Some machines are designed for specific label formats or product shapes.

- Ease of Maintenance and Operation: Choose a machine that is user-friendly and easy to maintain. Simplified maintenance routines help in minimising downtime and keeping the production line running smoothly.

- Integration: The applicator should integrate seamlessly with your existing production setup. Consider whether it can be easily incorporated into your current workflow without major modifications.

Applications of Automatic Label Applicators Across Industries

Automatic label applicators find applications across a variety of industries, each benefiting from their unique capabilities.

- Food and Beverage Sector: In this industry, label applicators ensure that products are labelled quickly and accurately, which is essential for compliance with health and safety regulations. They handle diverse packaging formats, including bottles, cans, and boxes.

- Pharmaceuticals and Healthcare: Precision is critical in the pharmaceutical industry. Automatic label applicators ensure that medication and medical supplies are labelled correctly, which is vital for patient safety and regulatory compliance.

- Manufacturing and Consumer Goods: For manufacturers and businesses producing consumer goods, automatic label applicators improve the efficiency of the packaging process, handling everything from cosmetics to electronics with speed and accuracy.

The Future of Automatic Label Applicators

The future of automatic label applicators is promising, with continuous advancements in technology. Emerging innovations are expected to enhance the functionality and efficiency of these machines.

- Technological Advancements: Future developments may include integration with advanced data systems, allowing for real-time monitoring and adjustments. Smart sensors and machine learning algorithms could further enhance accuracy and operational efficiency.

- Industry Trends: As automation continues to evolve, the focus will likely shift towards even greater efficiency and flexibility. The trend towards customisation and smaller production runs will drive the development of more versatile and adaptable labelling solutions.

Takeaway

Automatic label applicators represent a significant advancement in the world of product labelling. Their ability to enhance efficiency, accuracy, and cost-effectiveness makes them a valuable asset in modern packaging operations. As technology continues to evolve, these machines will undoubtedly play an even more integral role in shaping the future of industrial labelling.

Reflecting on the evolution of labelling technology, it is clear that automatic label applicators have revolutionised the way products are packaged and presented. Their continued development promises even greater enhancements, making them a pivotal component in the future of efficient and accurate labelling processes.